Products

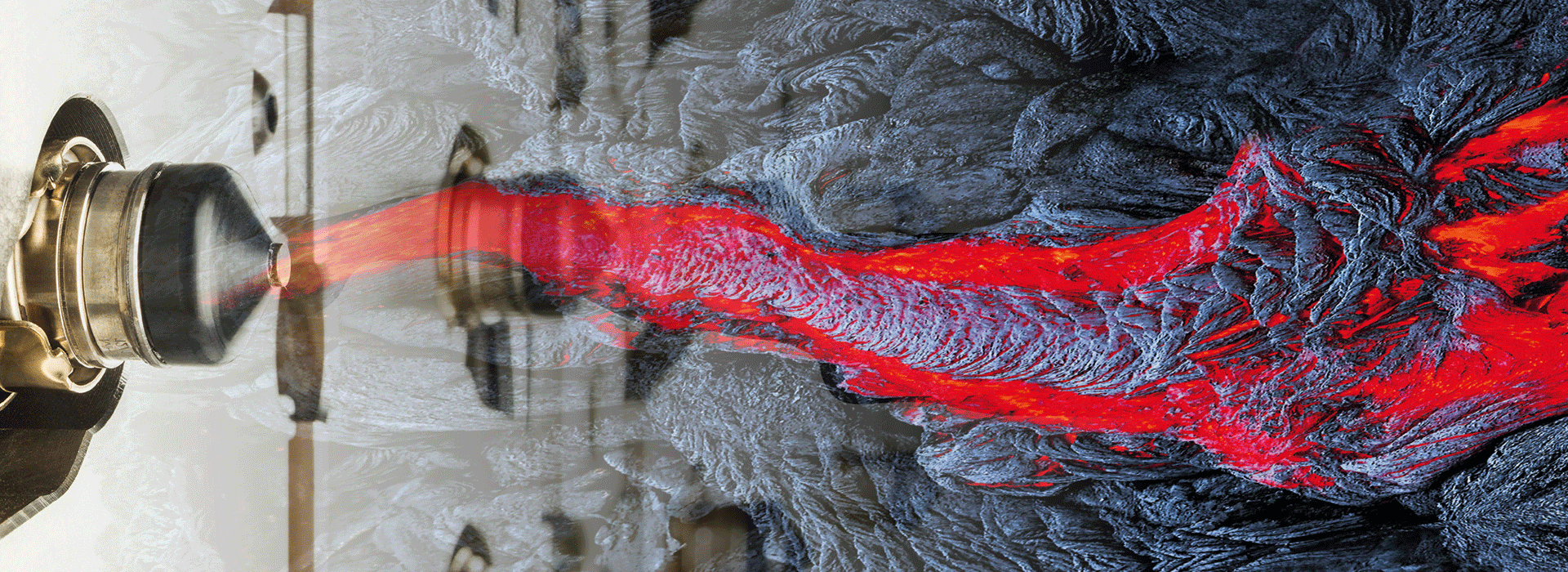

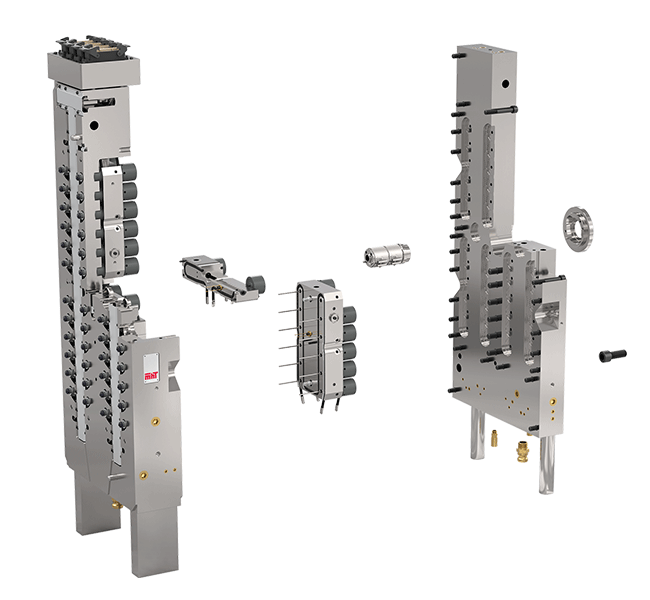

The basis for the extraordinary start-up performance the quick cycle times of our PET molds are the manifold systems which are developed and processed on the premises. We are a renowned partner of the packaging industry and, in addition to preform molds, we have also equipped screw-cap molds and technical part tools with manifolds.

- Naturally balanced melt flow guarantees uniform filling of all cavities

- Even temperature distribution provides for homogeneous melting for high-quality surfaces

- Individual tip control for crisp clean gates

- Optimized melt channels for quick material / color change

- Robust design for a long life

- Use of efficient components for cost reduction

- Easy maintenance and reduced spare parts provisioning

Advantages

- Perfect preform quality

- Less PET dust

- Broad process window

- Longer maintenance intervals

- High energy efficiency

- Reduced water consumption

- 100% compatible with existing cold sides

- Integrated digital cycle counter

- Homogenous temperature balance

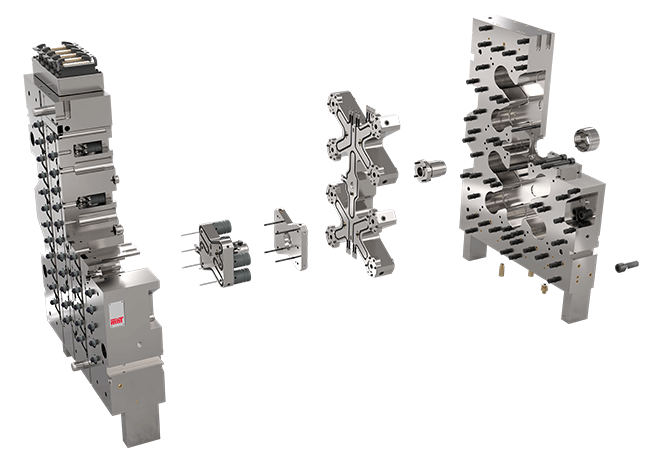

Technical Features

- 48 to 144 cavities

- Available for Sacmi, Husky, Niigon systems

- Two-plate design

- Modular hotrunner packages

- Cooled adapter plates

Advantages

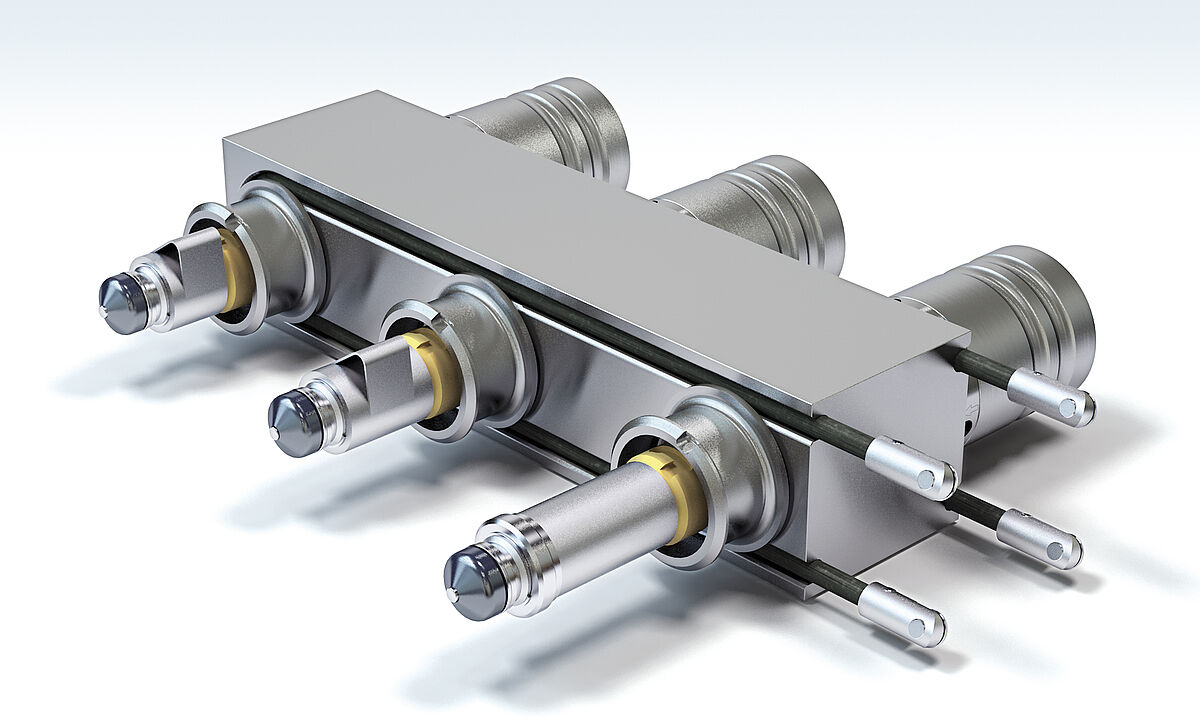

- Compact construction

- Short residence time

- Easy to maintain

- Robust design for a long life

- Suitable for all systems with a low number of heating zones

Technical Features

- Available for all well known PET sytems: Sacmi, Husky, Niigon, KraussMaffei, Netstal, Sumitomo, Milacron etc.

- Systems up to 192 cavities

- For even more efficiency available with Vulcan components

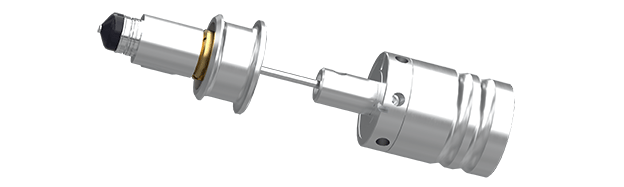

Advantages

- Quick and easy accessibility to all components

- Individual nozzle inserts for different applications

- High energy efficiency through thermal separation

- Reduced heat loss to the environment

- Optimized needle adjustment for perfect sprue

- Convenient exchange of sealing ring during assembly

- No leakage issues

- Long maintenance intervals