News

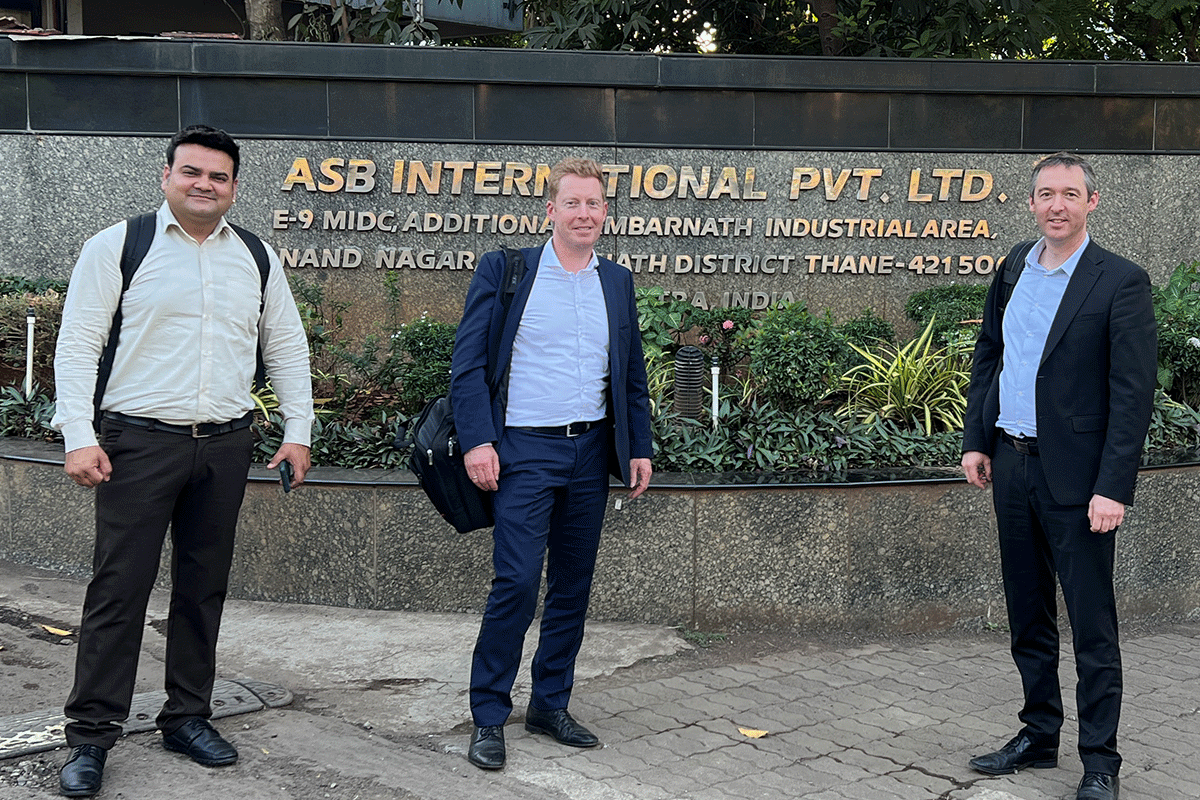

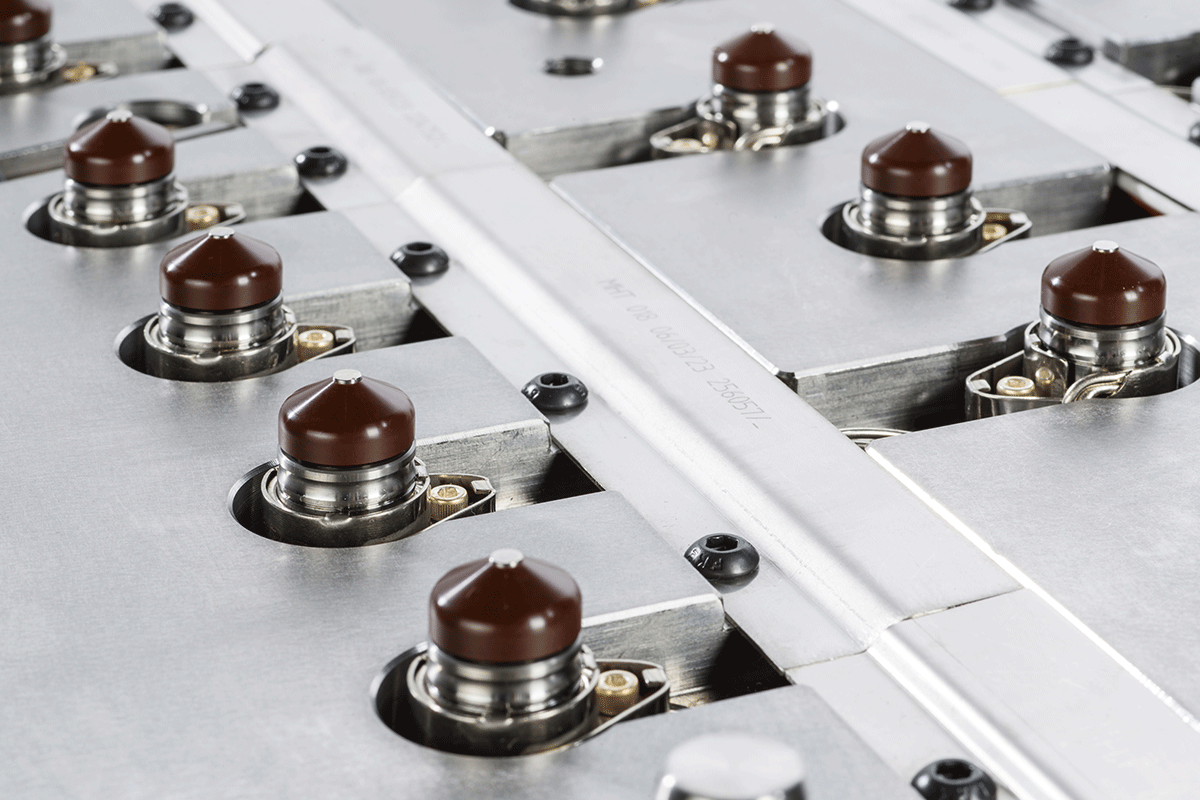

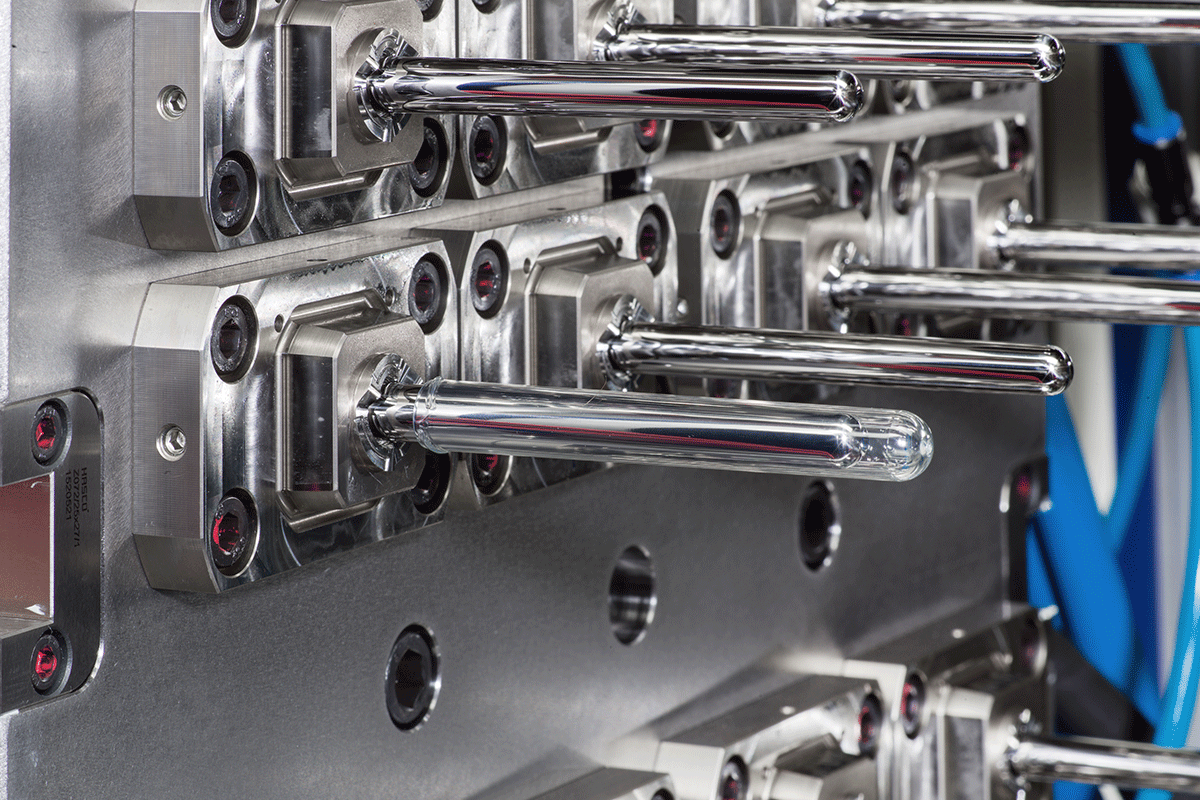

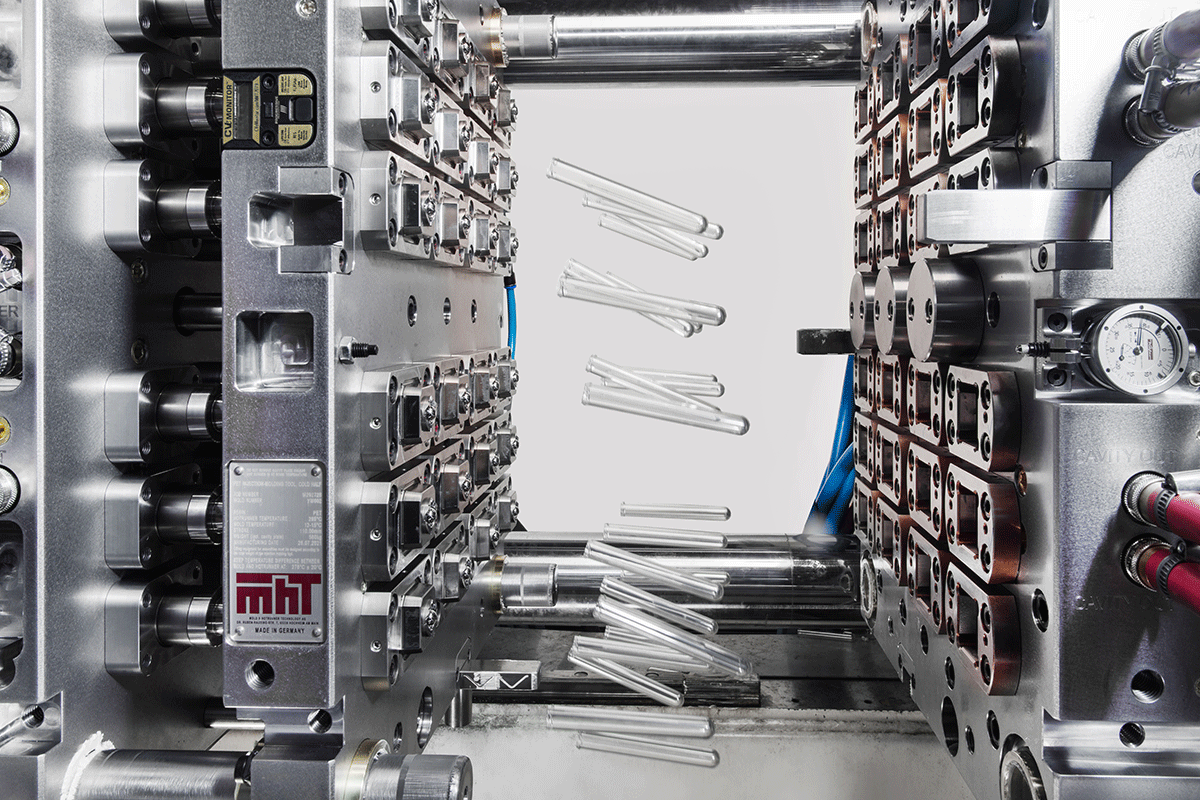

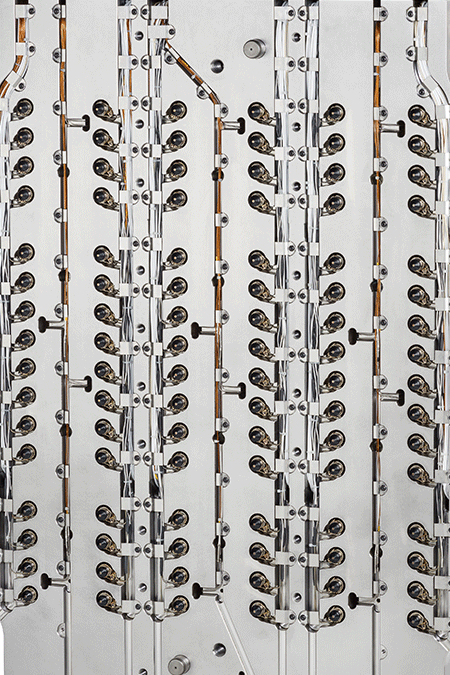

Celebrating a Milestone in PET Preform Production! MHT and ASB's Successful Collaboration Reaches 200 Hotrunners Delivered! We are thrilled to announce a remarkable achievement in our collaboration between MHT and ASB in the world of PET preform production. Together, we have reached a significant milestone of delivering around 200 high-performance PET hotrunners for ASB's renowned injection molding machines!

For years, MHT has been at the forefront of delivering cutting-edge PET hotrunner systems, while ASB has established itself as a global leader in injection molding technology. This collaboration has proven to be a winning combination, resulting in exceptional performance and unrivaled quality in PET preform production. Reaching the milestone of 200 hotrunners delivered is a testament to the trust and confidence placed in this collaboration. Our commitment to excellence and continuous improvement has been the driving force behind this achievement.

By leveraging our collective expertise, innovation, and relentless pursuit of perfection, we have successfully provided our customers with state-of-the-art hotrunner solutions that meet and exceed their expectations. This milestone not only highlights our ability to deliver high-performance PET hotrunners but also showcases the strong collaboration and synergy between MHT and ASB. We would like to express our deepest gratitude to our dedicated teams who have worked tirelessly to ensure the success of this collaboration. Their passion, expertise, and commitment to delivering excellence have played a pivotal role in achieving this significant milestone. As we celebrate this achievement, we remain committed to pushing the boundaries of innovation, delivering unmatched quality, and providing comprehensive solutions to our customers. The journey doesn't end here. We will continue to raise the bar, set new standards, and redefine PET preform production together.

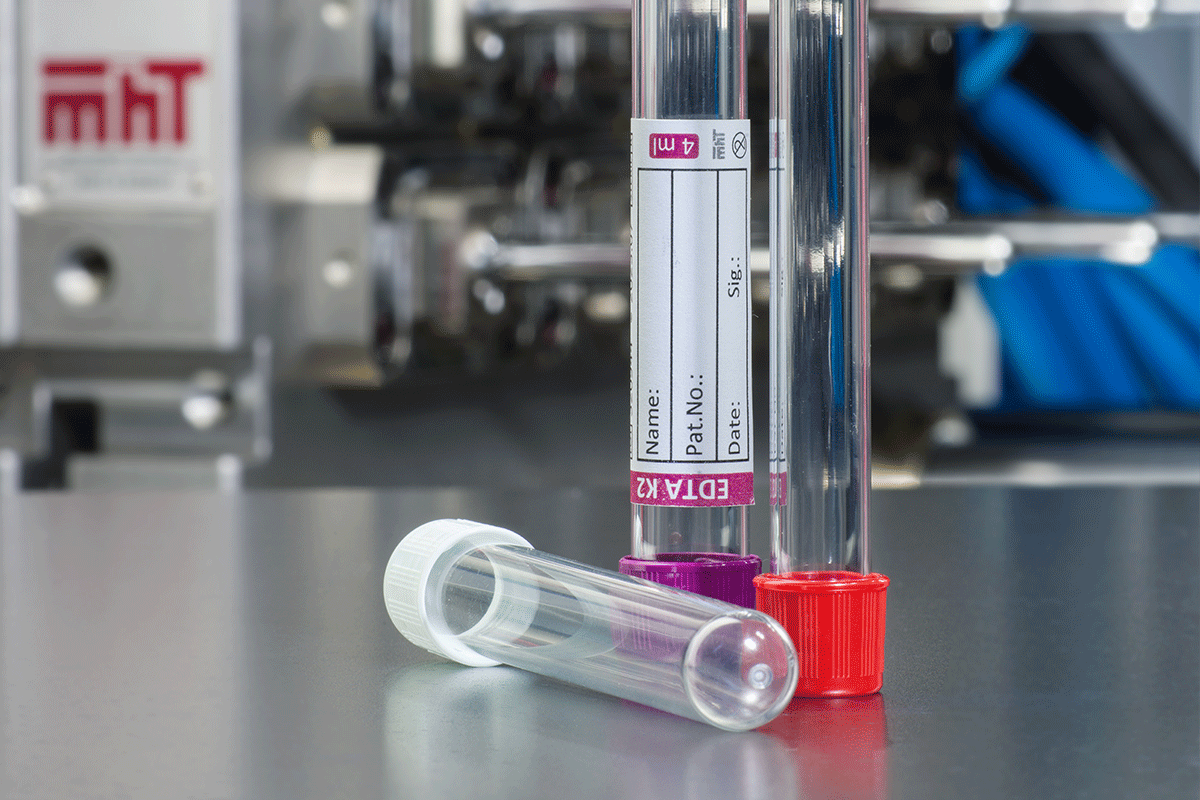

MHT and KEBO AG have announced a partnership to develop their businesses and provide complete Blood Collection Tube (BCT) solutions to their customers. Due to the strong market need for diagnostic and laboratory applications, both companies see great synergies in working together and decided to cooperate to develop their businesses. The primary objective of this collaboration is to offer the best solutions for blood collection systems. Please click her for more information.

In the course of realigning our Customer Service, we are proud to present our new Head of Customer Service, Jürgen Lippert. In future we will focus even more closely on our proactive customer support throughout the entire life cycle of MHT’s products. With our high-precision injection molds for PET preforms, electronic parts, handling and digitalization components are increasingly gaining in significance. As a trained electronics technician, Jürgen Lippert is fully qualified to develop innovative service concepts in this area as well. He has extensive experience in field service, after sales and training as well as many years of leadership. Jürgen Lippert succeeds Rainer Petry, who will move on to new professional challenges. MHT thanks Rainer Petry for an excellent cooperation and wishes him all the best for the future.

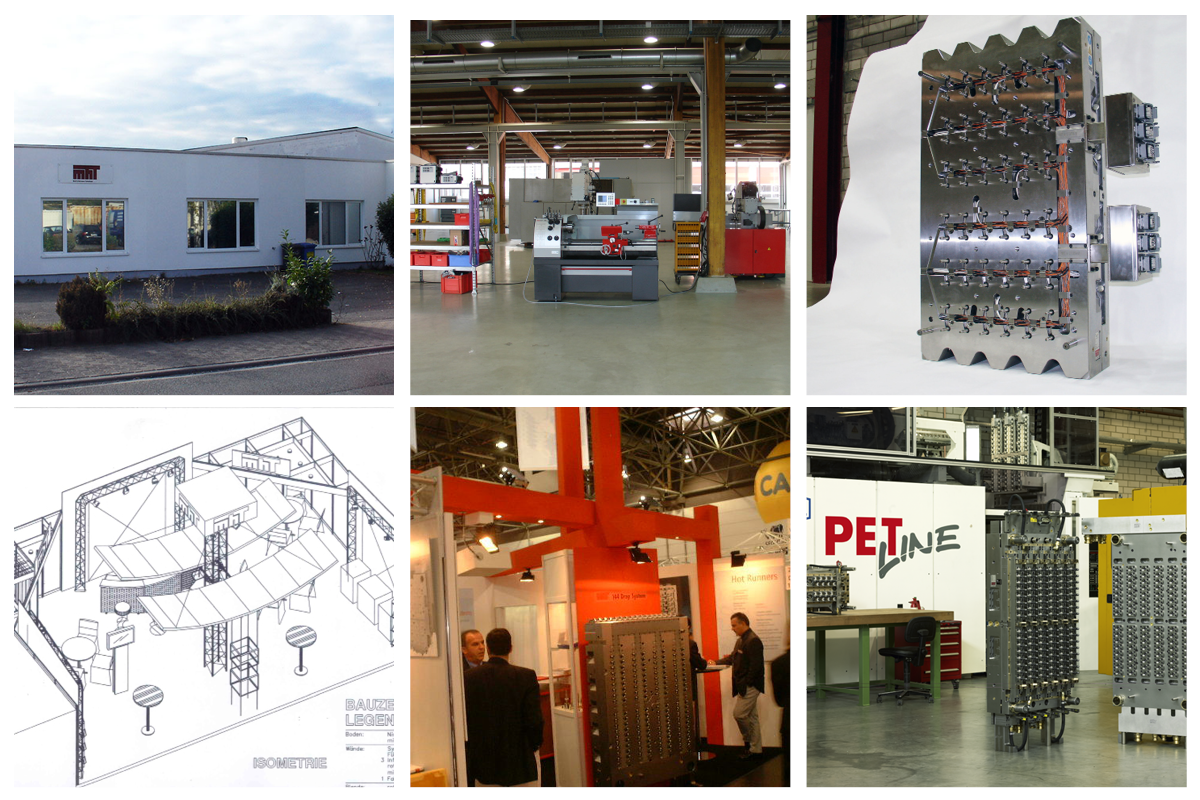

As time goes by: It's been 25 astonishing years since the foundation of MHT by 11 enthusiastic partners with a lot of technical expertise - and we are still innovative and driven by progress. We constantly overcome limitations, shorten cycle times and increase the output of PET preform systems. What has stayed the same is our motivation to build high cavity molds for all major PET systems in the market. Due to the current situation it is uncertain when we will be able to clebrate. We will keep you informed.

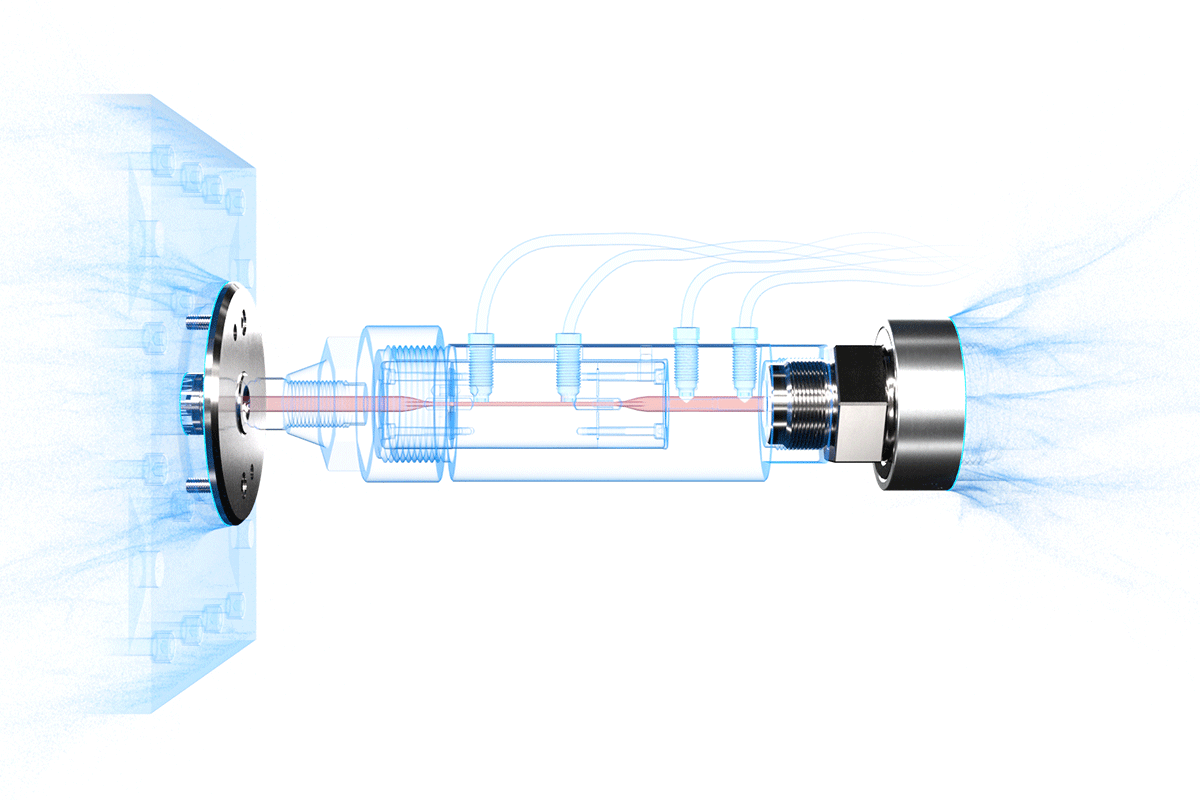

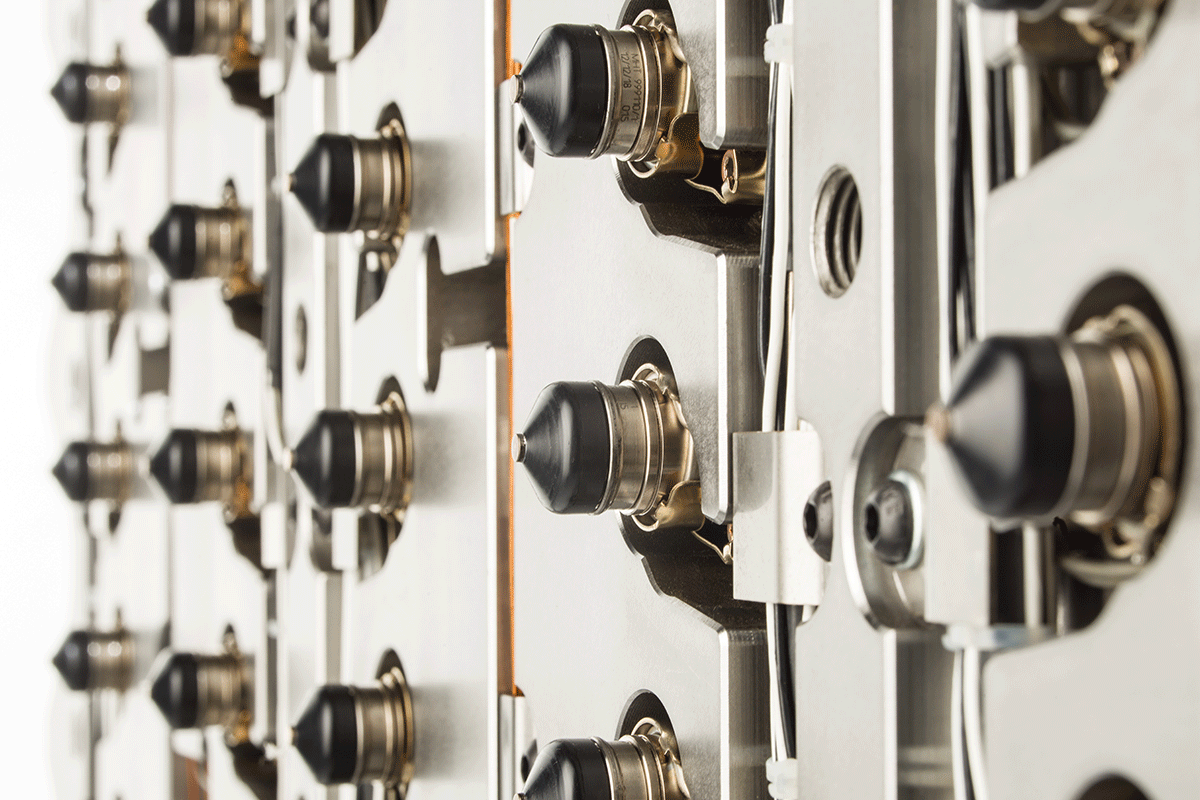

Less PET dust and lower resource consumption, and yet improved balancing and longer maintenance intervals: at K2019 MHT presented the new hotrunner generation optiRUN, that is capable of meeting the highest demands. It is particularly suited for the processing of rPET and is the result of a multi-year development project supported by the Darmstadt University of Applied Sciences. Here you can read more.

Among beverage producers, the Tibet Glacier Mineral Water Co.,ltd (TWR) can boast production facilities with the highest altitude in the world: situated 5,100 meters above sea level, the company fills bottles with the purest glacier water. It makes use of an MHT tool – and more are soon to follow. TWR was founded in 2006. In this remote area near Lhasa, TWR's almost 460 employees obtain premium water that has been filtered through many rock strata and heated to around 24 degrees Centigrade using geothermal energy. The company handles all production steps in-house: from water treatment and bottle manufacture, to bottling and quality control to marketing.

Since 2018, a 16-cavity tool supplied by MHT produces preforms with a 38-mm-thread and 100g weight on a Husky HyPet 225. Fully blown-up, it offers a volume capacity of 4 liters. The decisive factor in deciding on this tool made in Germany was its precision. After all, containers that are bottled at an altitude of over five kilometers and that are then sold at sea level – for example in Hong Kong – must be able to handle great differences in pressure. The preform absolutely cannot have any weak points. Mr. Yue, General Manager at TWR, is very satisfied with the progression of the project: "Delivery time, product quality and the support by the MHT team – everything worked perfectly."

It's a contender in the heavy-weight class: the new 5-axis milling machine from MHT, a Mikron HPM 1850 u, can process large workpieces such as sliding rails – this is made possible by travel paths of 1,850 x 1,400 x 850 mm as well as high travel speeds. The machine collects the workpieces itself via a rotary table and a pallet station with three storage slots, processes them and then puts them back in place. Of course the unit also features the automatic changing of milling cutters and drills from a magazine containing a total of 150 items. MHT has invested a million Euro in this unit. Klaus Wegmann, Head of Production, is delighted with it: "We're able to significantly increase our performance capacity with the Mikron 1850."